When choosing a technology or method for the manufacture of parts and prototypes, many doubts may arise. Therefore, it is essential to know the characteristics of the different manufacturing processes and materials.

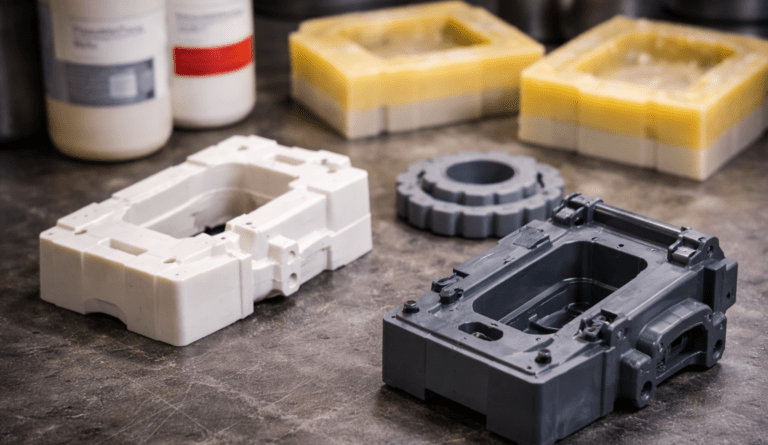

If we think of the most relevant technology for the production of small series of plastic parts, it is very likely that two come to mind: vacuum casting and plastic injection molding.

When comparing these technologies to make a decision, many questions usually arise: Which technology is best for my project? What are the differences between them? Which materials are available?

In this article we give you answers to all these questions:

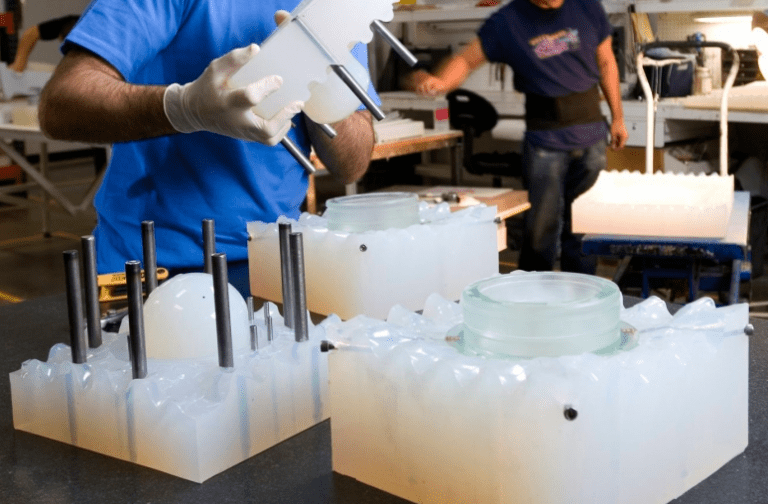

Benefits of vacuum casting of silicone molds

Vacuum casting is an ideal process for manufacturing short runs of plastic parts, making it a suitable technology for a wide range of industrial and commercial applications. Some of its main advantages are:

- Very fast production times: vacuum casting is a very flexible and fast to implement technology. It has an ideal responsiveness for dynamic sectors such as the medical industry, robotics or automotive.

- Parts with complex geometry or thick walls: vacuum casting is also an ideal production process for projects with particular angles and delicate demolding. Its elasticity allows the extraction of complex geometries without any risk of deformation.

- Increased strength and durability: vacuum casting allows for an even distribution of the resin around the reinforcement, resulting in stronger and more durable parts.

- Lower initial cost for molds: the cost of polyurethane is low, which makes the manufacturing process very economical.

- Less material waste: this process allows better control over the amount of material used, which reduces material waste.

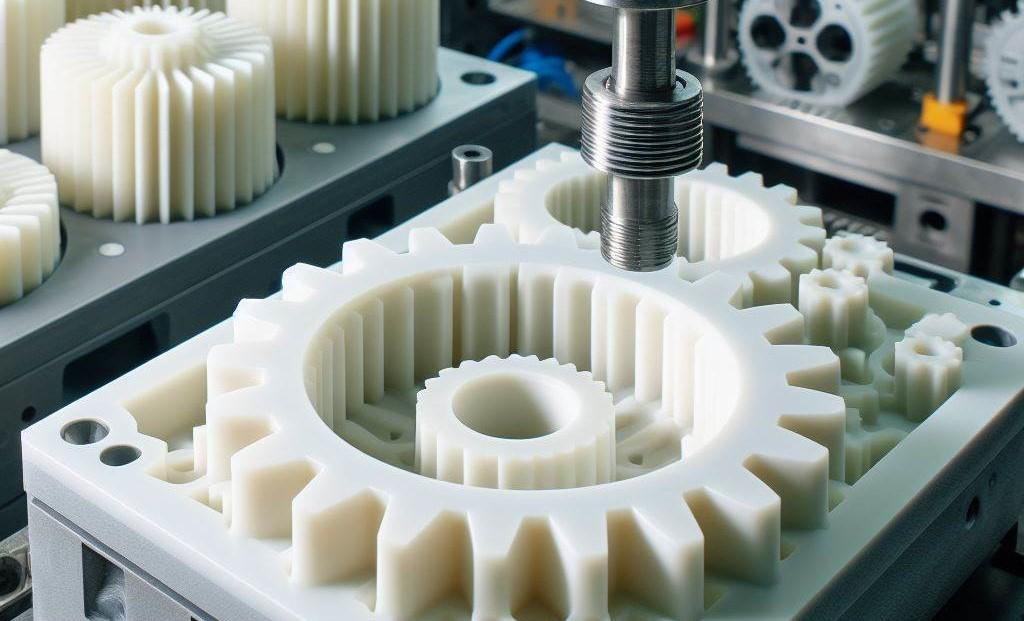

Advantages of plastic injection molding

Plastic injection molding is chosen in many situations because of its ability to produce large-scale parts with high precision, consistency and efficiency. These are some of its advantages:

- High precision: plastic injection molding allows the production of parts with high precision and tight tolerances.

- Wide variety of materials: it is a process compatible with a wide variety of plastic materials, which allows the manufacture of parts with different physical properties.

- Lower cost per unit in large volumes: due to process efficiency and mass production capacity, the cost per unit of parts produced tends to be lower when produced in large quantities. Although the initial setup cost of an injection molding machine is relatively high.

How to choose the right manufacturing process?

When deciding between vacuum casting or plastic injection molding, the following factors need to be considered:

Firstly, the volume of production is an essential element to take into consideration. Vacuum casting is best for small production runs or prototypes, while plastic injection molding is ideal for medium to large production runs.

Secondly, the cost of tooling is also important. The tooling for vacuum casting is much more economical than for plastic injection molding.

On the other hand, it is necessary to consider the materials. Only a limited set of curable plastics can be used in vacuum casting, whereas a wide range of thermoplastics and thermosets can be used in plastic injection molding.

Finally, another important factor is the service life of the parts. Silicone molds for vacuum casting are not as durable as the hardened steel or aluminum molds used in injection molding, which can last for years or even decades.

Ultimately, each technology has its advantages and limitations, so the choice of the appropriate manufacturing process will depend on the needs of the project.

At Proto&Go! we aim to provide you with the best service to develop your prototypes at very competitive prices, using the most advanced technologies, such as CNC machining, silicone molds and 3D printing.

What are you wating for? Request your quote now!