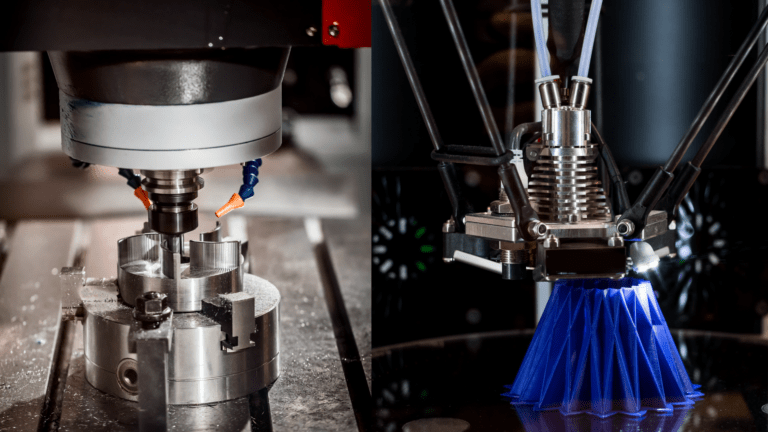

CNC machining is a part and prototype manufacturing process suitable for a variety of industries such as aerospace, automotive and medical.

On the other hand, it is also a suitable process for many metal or plastic materials. The choice of the optimum material for the manufacture of parts by CNC machining will depend mainly on the specific needs of the project.

The importance of the right choice of material in machining

When choosing a material it is essential to take into account its application or the project we are carrying out, since there are countless options and each one has different advantages and limitations.

Properties such as strength, toughness, hardness or conductivity are factors to be considered when choosing the right material for CNC machining.

In this article we tell you some of the basic characteristics of the most common metals:

Different types of metals for CNC machining

Aluminum

Aluminum is one of the most widely used materials today. This is due to its low density and excellent properties such as high strength, ductility and corrosion resistance.

On the other hand, it is also an easy material to machine, although this factor will depend on the heat treatments used on the material.

It is a material with a large number of uses and applications thanks to its versatility. Although almost all industries use it for a wide variety of applications, these are some of the most common examples:

- Automotive industry: it is commonly used for the manufacture of engines, frames and other components due to its strength-to-weight ratio.

- Aerospace industry: aluminum is used for structures, fuselages or airframes for the same reason as in the automotive industry.

- Construction industry: it is used to build components such as windows or doors, as it is a sector in which weight and corrosion resistance are critical in the manufacture of parts.

Steel

Another of the most commonly used materials is steel, as it has a relatively low cost and very useful properties. There are a wide variety of steels that are manufactured using different alloys and each has different material properties. The two most common types of steel are stainless steel and carbon steel.

First, stainless steel has a high resistance to corrosion. It is a solid material ideal for machining and highly recommended for use in the aerospace and automotive industries and even in jewelry manufacturing.

Other advantages are that it does not require post-welding treatment and is recyclable.

On the other hand, carbon steel, commonly known as iron, is a corrosion-prone material with good strength and low cost. Thanks to its properties, it is an ideal material for the manufacture of industrial parts. It is also an easily weldable material with good toughness.

Copper

Unlike steel and aluminum, copper is not commonly used in structural applications because of its low strength and high ductility. It is normally used for components such as wires or cables because of its high thermal and electrical conductivity.

Copper is also a durable metal, as it can be recycled an almost unlimited number of times without losing its mechanical properties.

It is an ideal material for the manufacture of CNC machined prototypes and electronic components.

Brass

Brass is the alloy of copper and zinc. It is a material that not only retains much of the thermal and electrical conductivity of copper, but can also be alloyed with other elements to achieve greater resistance.

The most common uses of brass are items such as locks, gears or musical instruments.

On the other hand, due to its bright finish and high machinability, it can also be used for decorative items.

In short, it is important to bear in mind that each material has different properties and affects the manufacture of CNC parts differently. On the other hand, it is also necessary to consider that the industry is in continuous evolution and is constantly learning new ways to manufacture better materials, alloys and tools for the machining process.

At ProtoGo! we offer the best CNC machining service for your parts and prototypes. In addition, through our website you will be able to receive your quote in less than 24 hours.

What are you wating for? Contact us or request your quote now!