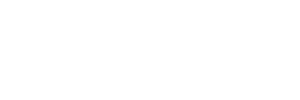

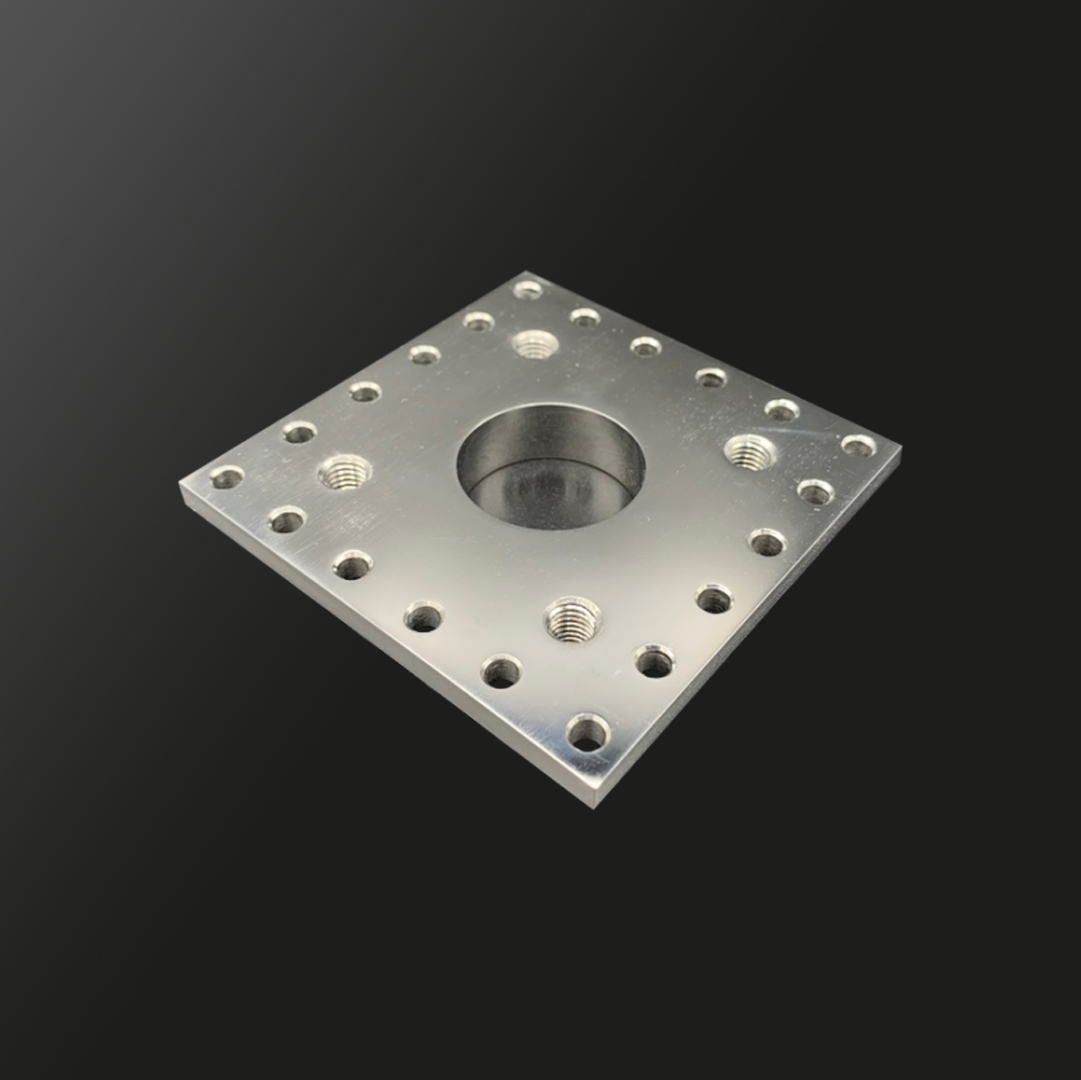

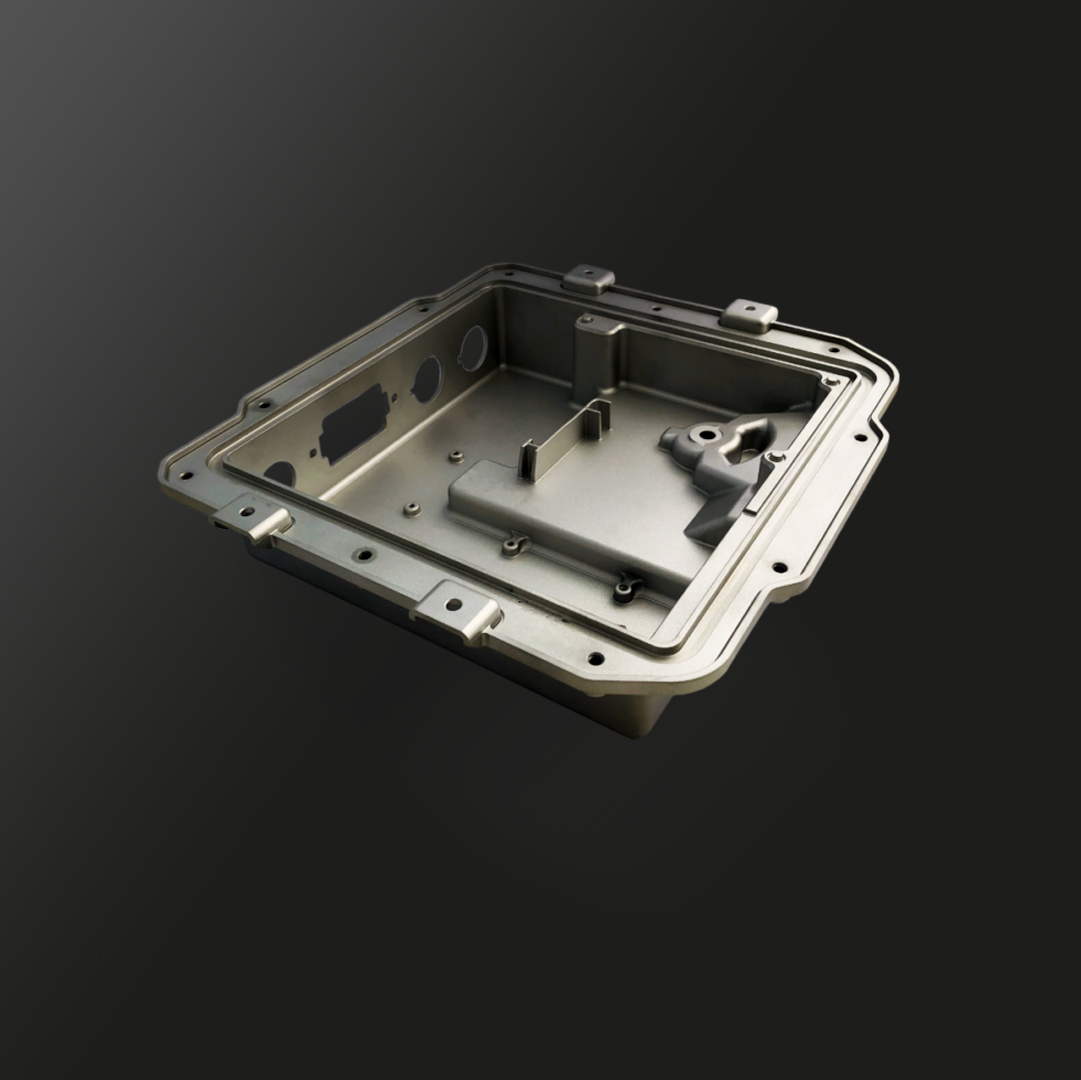

CNC machining

Perfect for every production requirement

from prototype to series

Request your quotation with a CAD file to obtain

the quotation of your parts

Parts manufactured and delivered in just 8 working days

PERSONALISED PARTS ACCORDING TO YOUR FILES

What CNC machining is it about?

Milling

Turning

We use CNC machining for high precision manufacture parts and precise We have a range of materials, including plastics and metals. We offer solutions for industrial machining through our CNC machining centres which have a capacity of 3, 4 and 5 axes. Our online service, allows us to provide quotations and feasibility analysis in less than 24 hours.

At Proto&Go! we implement the Lean philosophy in all of our machining processes to optimise production, reduce response times and offer a faster and more efficient service to our customers. All our parts have rigorous quality control to ensure that they meet our customers’ specifications and design requirements

Thanks to our CNC machining centrewe manufacture high quality and precision parts. We offer the best solutions for industrial machining,CNC of parts in order to become your online manufacturing partner. Our experts teams’offers prototyping solutions in less than 24 hours, optimising costs and minimising response times. Shall we talk? Contact us and request your quotation!

MANUFACTURING PROCESSES

Advantages of CNC machining

CNC machining includes the processes of turning, milling, wire cutting and EDM.

This is the best manufactured process and It’s ideal for meeting the majority of product development and parts needs, always starting from the geometry defined by a 3D file.

Here are some of the benefits of precision machining:

precision machining in both, metal and plastic:

Highly precise

Obtaining strict tolerances

Suitable for most materials

Excellent surface finish

Low investment in setup costs

Scalable volumes from 1 unit

Production agility

High precision parts and possibility of

different finishes

Upload your CAD files to our platform to make the management process faster and more efficient.

A 3D file is always essential and should only contain a one piece.

To indicate the threads present on a part, you must also upload a drawing in .pdf format to the platform.

To use our service it is no longer necessary to invest your time in making all the annotations on the drawings, the 3D file is enough

Different finishes for parts produced in high precision machining