Sustainability has become a crucial issue within the industry. Over time, social developments make ecological standards more and more demanding. In this context, the focus is very much on the manufacture of parts through the machining process.

Factors such as the responsible use of raw materials, the reuse of materials and the reduction of pollution in the manufacturing process are becoming increasingly important and necessary to contribute to reducing the environmental footprint.

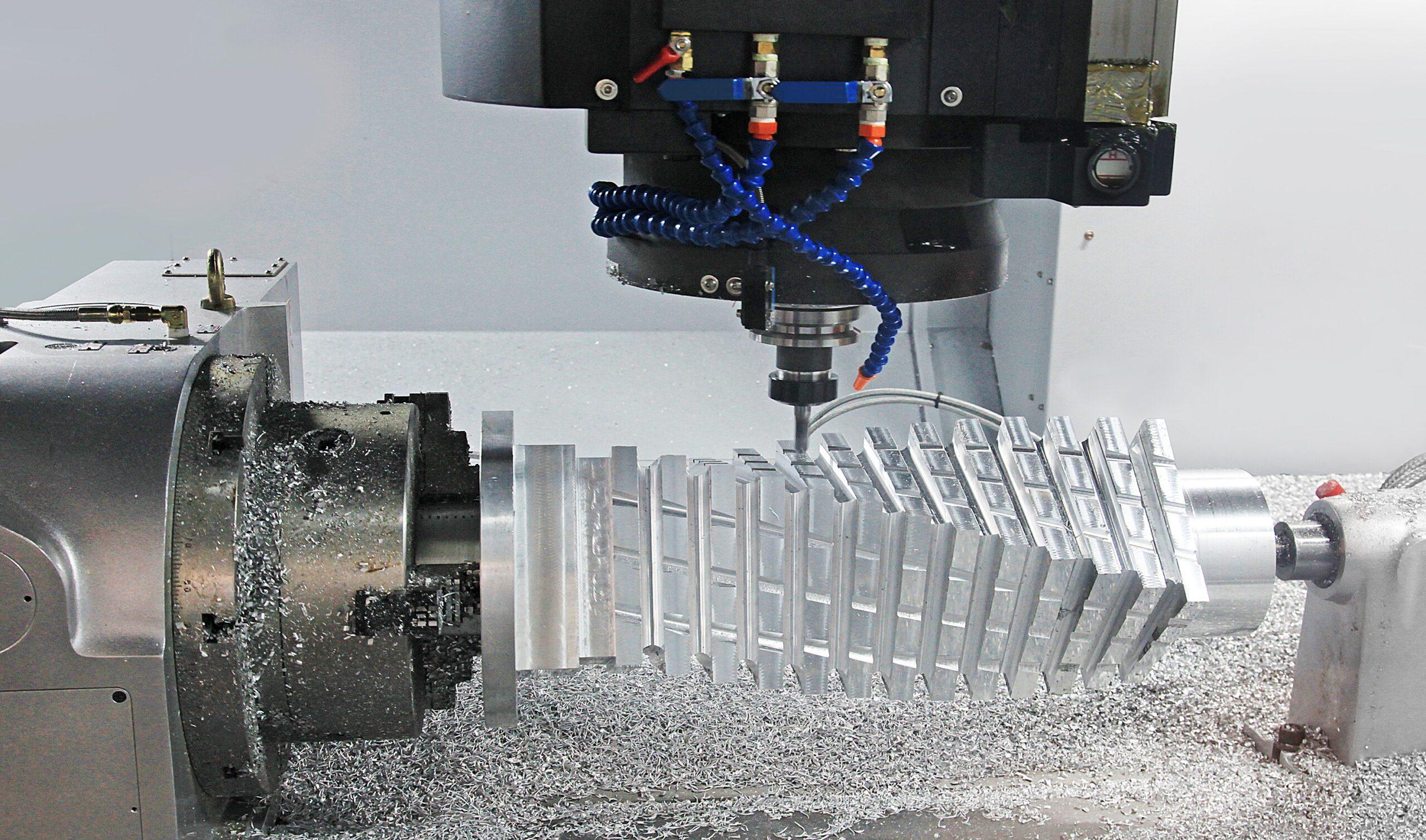

Combining new technologies, innovative designs and new machining strategies results in sustainable machining with the ability to achieve crucial factors in industrial processes: maximum productivity, extended tool or machine life and minimum energy consumption.

How can a machining company be sustainable?

First of all, we could say that tool life is at the core of this concept. It is influenced by the proper choice of material and tool design, however, cooling, machining strategy and the use of correct cutting parameters are also very important to maximize tool life.

On the other hand, a very good option if the tool wears out is to resharpen, since it is often not essential to buy a new one immediately. This not only saves costs, but also avoids unnecessary waste.

When tools or machinery have reached the end of their useful life, it should be considered that the raw material can be reused thanks to advanced recycling processes.

Finally, it is essential to go for innovative design, i.e. multifunctional tools or milling systems with interchangeable heads, as this factor can reduce the total consumption of tools required for machining the parts.

Monitoring of machining: sustainability and productivity at the same time

Machining monitoring systems collect data via external sensors or directly from the machine. This data is then analyzed by an algorithm to identify possible faults that may hinder the machining process.

Normally, this control is performed manually, therefore, corrective actions can be taken in real time, resulting in shortened tool life, increased waste generation and reduced production.

In contrast, with real-time machining monitoring, the set reference value can be adjusted to machine life and raw material conditions to avoid material waste and solve unpredictable failures.

In short, we can say that in the fast-paced and changing world in which we live, where industries are constantly evolving, the concept of sustainability has gained prominence. This change applies to all sectors, including CNC machining.

At Proto&Go! we offer the best solutions for industrial machining and machining of parts for your projects.

Request your quote now and receive it in less than 24 hours!