Tolerances in CNC machining are a critical aspect that determines the precision and quality of the manufactured parts. Therefore, understanding how tolerances work is essential for any engineer or manufacturer who wants to produce components that meet exact specifications and perform correctly in their end applications.

In this article, we tell you what tolerances are, how they are applied in the CNC machining process and why they are so important.

What are tolerances in CNC machining?

In CNC machining of parts, tolerances can be defined as the acceptable range for a dimension, determined by the designer, that ensures the proper functioning of the part based on its form, fit and function.

In CNC machining, tolerances can be defined as the acceptable range in which a parameter can deviate from its intended value.

In addition, there are different types of tolerances, such as limit tolerances, unilateral or bilateral tolerances or a system of tolerances known as geometric dimensioning and tolerancing (GD&T).

Tips on tolerances in CNC machining

First of all, it is essential to keep in mind that tolerances are a very important factor for your design. However, it is also important to avoid unnecessary tolerances, as tight tolerances often lead to an increase in expendable parts, longer cycle times and special measuring tools.

On the other hand, it is also essential to take into account the properties and characteristics of the material, since the difficulty of machining a part to a given tolerance depends to a large extent on the material from which the part is manufactured.

General and specific tolerances in Proto&Go!

At Proto&Go! we work through our online platform, which allows you to upload your 3D files and receive a quote in less than 24 hours.

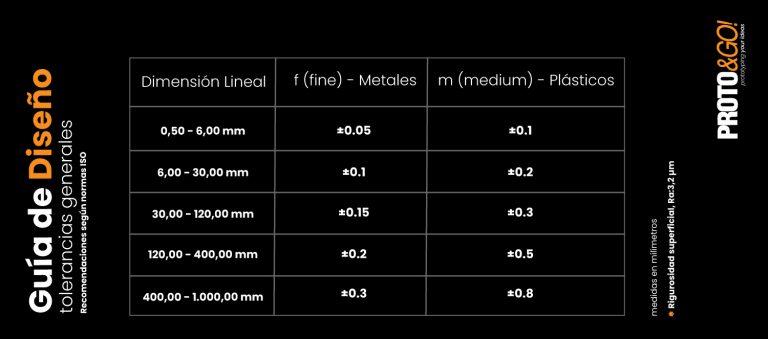

In case the quotation does not include a 2D drawing with a specific tolerance request, Proto&Go! will manufacture the parts according to ISO 2768fH for metals and ISO 2768mK for plastics:

In the event that the general tolerances are not sufficient for the functionality of the part, the designer or engineer shall indicate the required tolerances on a drawing.

It is important to note that the tighter the tolerances, the higher the manufacturing cost of the part, even doubling the cost of the part with standard tolerances.

On the other hand, if there are specific geometric tolerances or any other notation that must be complied with, it is important that these are also reflected on the attached drawing.

Finally, in order to minimize manufacturing costs, Proto&Go! recommends using specific tolerances only in those areas that are really critical.

Request your quote now quickly and easily through our website.