If you think of the most relevant technology for the production of short series of parts, the vacuum casting process usually comes to mind. Even so, you will probably have many questions such as: What are the differences between vacuum casting and other technologies? How can I choose the best production process for my project? …

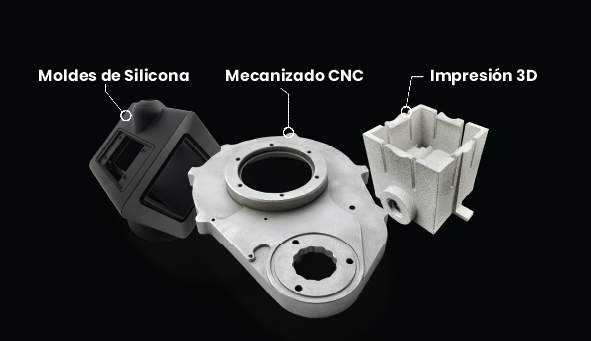

In this article we will try to solve all those doubts by explaining in a summarized way the differences between the three manufacturing processes we offer at Proto&Go!: vacuum casting, CNC machining and 3D printing.

Differences between vacuum casting and other processes

First of all, if we talk about production speed, vacuum casting can be fast for high volume production, while CNC machining can be slower (especially if complex parts are involved). On the other hand, additive manufacturing can be fast only for prototypes or small quantities.

Regarding costs, these can vary, but typically vacuum casting of silicone molds is more economical for large quantities and 3D printing for prototypes and customized parts. In contrast, CNC machining can be more expensive due to material requirements and machine time.

In terms of design flexibility and geometric complexity, both vacuum casting and 3D printing are flexible for complex designs. However, CNC machining of parts can have certain limitations on some geometries, especially compared to 3D printing, where more complex shapes can be built layer by layer.

With regard to materials, there are also some differences:

On the one hand, in vacuum casting there is a wide variety of materials (such as resins, plastics and metals), which can be used according to product requirements. In CNC machining, solid blocks of materials (such as metals, plastics and composites) are generally machined. And, in 3D printing, the variety of materials is extensive and includes plastics, metals, ceramics and resins. Thus, it offers great flexibility in the choice of material depending on the application.

On the other hand, with regard to material waste, in vacuum casting it can be minimal, since only the amount needed to fill the mold is poured. In the CNC machining, on the other hand, a significant amount of material waste can be generated, especially when milling parts from solid blocks. Finally, in 3D printing material waste is usually less compared to CNC machining, as material is added layer by layer as needed.

Ultimately, the choice between these three processes will depend on the specific requirements of the project, including production quantities, required accuracy, materials and part design.

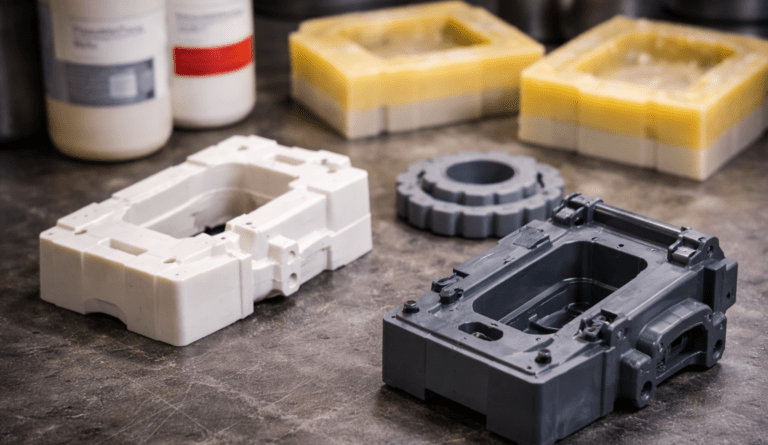

Why choose vacuum casting of silicone molds?

The manufacture of parts in silicone molds is an excellent process due to all the advantages and applications it offers. Some of the reasons why it is ideal to choose this production process are:

- The high precision of the polyurethane parts: this process can achieve replicas identical to the original.

- The wide variety of finishes offered by polyurethane casting.

- The wide selection of materials: there is a wide range of polyurethanes that simulate thermoplastic materials and rubber.

- Cost and production lead time: polyurethane parts manufactured by vacuum casting are shipped within 10 working days.

- The complex geometry of the parts manufactured by this process.

In short, at Proto&Go! we produce silicone molds of excellent quality to ensure constant repeatability of production. In conclusion, at Proto&Go! we produce silicone molds of excellent quality to ensure constant repeatability of production.

If you want to know more about silicone molds, you can do it through our platform.