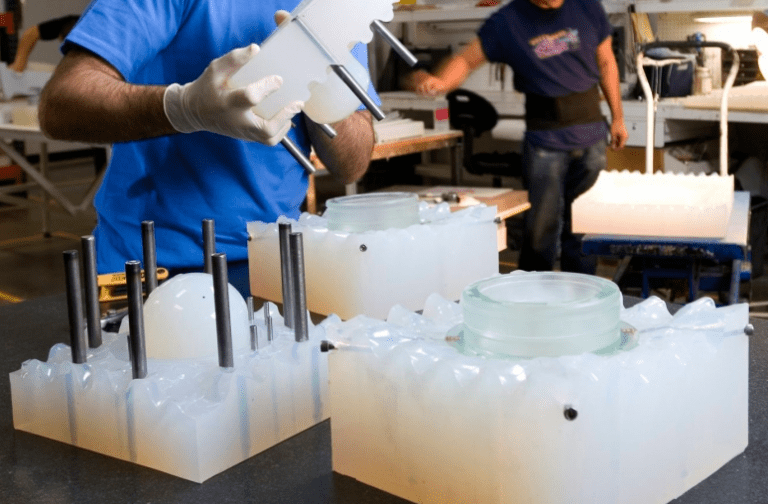

Vacuum casting in silicone molds is one of the most widely used technologies for manufacturing plastic parts in functional prototypes and small series. Thanks to silicone molding and the use of a wide range of polyurethanes, it is possible to obtain parts with a very good surface finish, tight tolerances, and mechanical properties adapted to each application. However, to obtain consistent results, it is essential to understand why certain common defects occur and how to correct them.

In this article, we analyze the most common problems in the manufacture of parts in silicone molds, explaining their origin and the most effective solutions both in terms of part design and the polyurethane casting process itself.

Air bubbles in vacuum washing: causes and solutions

Bubbles are one of the most common defects in vacuum casting and are usually directly related to the way the material flows and displaces air inside the silicone mold. They appear when air is trapped during filling or when the resin is not fluid enough to properly fill all the voids. In addition, a common cause is the presence of trapped air during the mixing of the polyurethane resin prior to pouring.

From a design perspective, this problem is often associated with molds for plastic parts with complex geometries, sudden changes in section, or high areas without proper air evacuation. Designing well-dimensioned sprues and strategically placed vents allows air to escape from the mold naturally during filling.

In the manufacturing process, controlling the vacuum cycle and selecting the resin are key. Working with polyurethanes of adequate viscosity and adjusting the casting speed promotes continuous flow, reducing the appearance of bubbles even in parts with fine details. As an additional best practice, pre-degassing the resin under vacuum before casting helps to remove air introduced during mixing, significantly improving the surface quality of the part.

Bond lines and flow marks in castings

Weld lines appear when two fronts of material meet inside the mold during vacuum casting. Although in many cases they are mainly a cosmetic defect, in certain applications they can affect the mechanical strength of the part.

This type of marking is usually related to poorly controlled material input or excessively long flow paths within the silicone molding. When the resin cools or begins to gel before bonding properly, the bond line becomes visible. They can also be accentuated by temperature differences between the mold and the resin or by excessive viscosity during filling.

To minimize this effect, it is advisable to simplify the material flow whenever possible, define a single casting point, and pay special attention to geometric transitions. Smooth radii and gradual section changes facilitate the even flow of polyurethane casting. At the process level, maintaining a stable mold and resin temperature helps the material fronts to fuse correctly.

Contractions and deformations in silicone molds

Contraction is an inherent phenomenon in many materials used in polyurethane casting and can lead to deformation or dimensional deviations if not taken into account from the outset of the project.

When manufacturing parts in silicone molds, shrinkage tends to be more pronounced when there are large differences in thickness or material concentrations in specific areas. A balanced design, with wall thicknesses that are as uniform as possible, contributes significantly to reducing this problem.

From the outset, choosing the right polyurethane is key. The possibility of working with a wide range of polyurethanes allows for the selection of materials with lower shrinkage and better dimensional properties. In addition, controlling the curing cycle and respecting demolding times avoids internal stresses that could deform the part. In applications with greater dimensional requirements, it is common to allow for tolerances or compensations in the design of the pattern or mold to absorb the shrinkage inherent to the selected material.

Diagnosis and optimization of the vacuum casting process

In vacuum casting, there is no single cause for each defect. In most cases, problems arise from a combination of the part design, mold design, and process parameters. Therefore, a good initial diagnosis is essential to reduce iterations, development times, and costs.

Analyzing material behavior, flow within the mold, and manufacturing conditions allows for the optimization of silicone molding from the early stages of the project, especially when dealing with small series or pre-industrial process validations.

Manufacturing parts in silicone molds at Proto&Go!

At Proto&Go!, we use vacuum casting as a flexible and efficient solution for manufacturing plastic parts using silicone molds, both for functional prototypes and short runs. We work with a wide range of polyurethanes to adapt the mechanical, thermal, and aesthetic properties of each part to its end use.

Our team supports customers by advising them on geometry, material selection, and process definition, with the aim of minimizing defects and obtaining reliable results from the very first units.

If you are considering vacuum casting for your project and want to ensure the quality of your parts from the outset, we can help you define the best manufacturing strategy for silicone molds.

In addition, at Proto&Go!, we have managed to digitize the manufacture of parts from an online platform and thus lead the vanguard of prototype production. In this way, we have managed to make the latest production technologies available to any user in a simple, fast and economical way.

Don’t wait any longer and request your quote through our platform!