As we have explained in recent articles, CNC machining for part and prototype manufacturing has many benefits and can be used for a wide variety of applications.

Here is a summary of the main reasons why you should choose CNC machining for the production of your parts.

Main reasons for choosing CNC machining

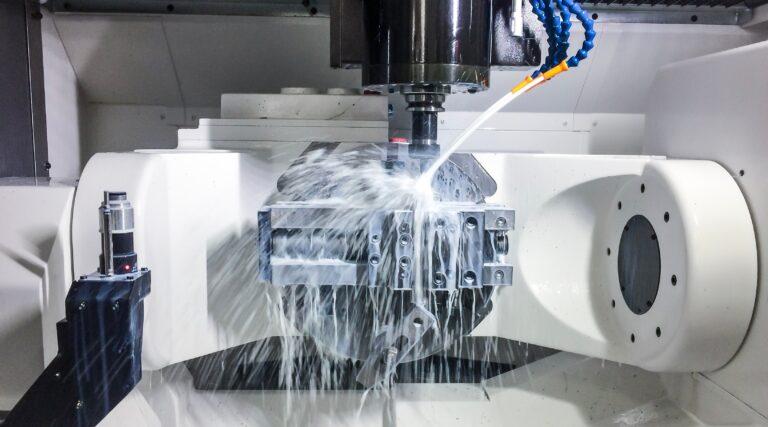

First and foremost, the extraordinary accuracy and precision it provides, thanks to the meticulous controls that monitor the cutting tool. These automated controls evaluate all aspects of the design, ensuring that the prototype produced is true to the desired reproduction.

On the other hand, if you are looking for speed and efficiency in the process, the choice of CNC machining of parts is ideal. Unlike other methods, such as injection molding, where manufacturers and developers must wait for the completion of the molds, CNC machining allows for faster execution. This feature also makes it the perfect choice for the creation of prototypes with unique or complex shapes, thanks to its outstanding customization capabilities.

Automation in CNC machining guarantees, on the other hand, high repeatability in production. Each manufactured part is virtually identical to the previous one, which is crucial in large-scale production and, above all, to maintain consistent quality standards.

In addition, it is important to highlight the optimization of material usage, as the cutting process is precise and can be programmed to minimize waste. This contributes to efficiency and production cost savings.

CNC technology also allows real-time monitoring and advanced control of the manufacturing process. Operators can adjust parameters as needed. This improves responsiveness and the ability to correct possible errors.

Another important point is compatibility with a wide range of materials. Machining can be performed on aluminum, plastics and even composite materials. This provides flexibility in the choice of materials according to the specific needs of your projects.

On the other hand, it is important to note that, unlike some manufacturing processes that require large volumes to be profitable, CNC machining is efficient even in small batch production. This is beneficial for companies that need to manufacture prototypes or limited batches of specialized parts and are looking for efficiency and cost-effectiveness in production.

Unlike other manufacturing methods that may require design-specific tooling and molds CNC machining uses versatile tooling and can adapt to different geometries without the need to constantly change tooling.

Technology integration and efficiency at Proto&Go!

Also noteworthy is the advanced programming of CNC machining, which allows for highly complex cutting operations. You can easily program intricate patterns, three-dimensional surfaces and complex sequential operations, which is essential for advanced part manufacturing. This is due to Computer-Aided Design (CAD) integration. CNC machining is seamlessly integrated with CAD software. This facilitates the transition from the digital design to the manufacturing process, allowing for greater consistency between the original design and the final product.

Another factor that improves overall process efficiency and maximizes machine uptime is automation, which significantly reduces downtime between the production of different parts.

On the other hand, the flexibility in the tolerance configuration allows to adapt to different quality requirements. Thanks to this, you can adjust tolerances to the exact specifications of your parts, which is crucial in industries where precision is paramount.

In addition, CNC machining can perform operations in several directions simultaneously, i.e. multi-axis operations, which facilitates the creation of more complex parts and reduces the need for multiple setups. At Proto&Go!, our state-of-the-art machinery has 3, 4 and 5-axis capabilities.

In short, CNC machining of parts offers an exceptional combination of precision, quality and repeatability, making it an unbeatable choice in the field of component and prototype manufacturing.

Don’t wait any longer, upload your plans to our website, select the material and request your quote!