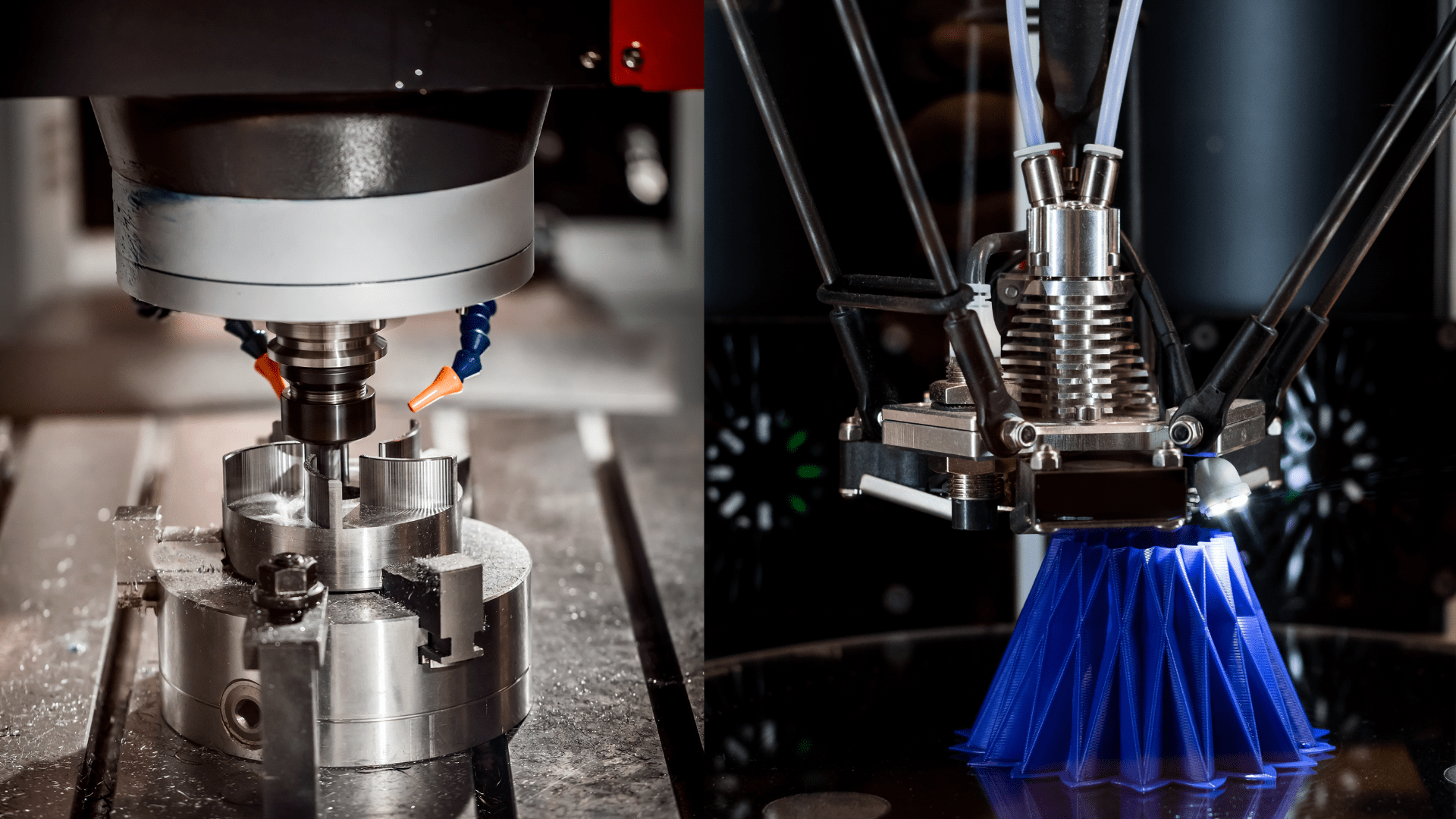

Both CNC machining and 3D printing are technologies with a strong presence in many industries today. In a nutshell, we can say that while 3D printing creates parts by building layers, CNC machining creates them by cutting them out.

But can these two technologies be used to complement each other or are they mutually exclusive?

For some projects or products, it is clear that a particular production process is more appropriate, but on the other hand, there are many cases where the combination of both technologies provides excellent results. A clear example of this is when a 3D printed part is manufactured and then CNC machining is used to polish the surface or add grooves or threads.

We can say that the key lies in recognizing the distinctive value and advantages offered by each technology and applying them in the design and product development processes in the most appropriate and efficient way.

Therefore, 3D printing and CNC machining can be used individually or combined at all stages of the process to achieve the full benefits of each for the manufacture of parts and prototypes.

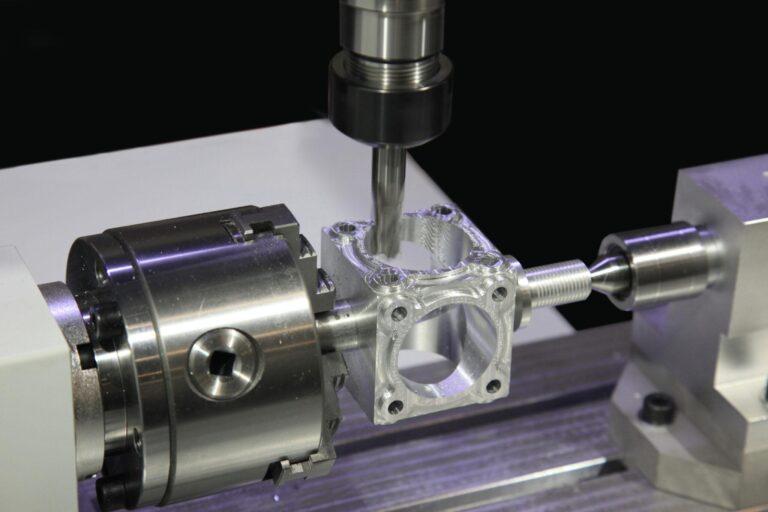

Top design tips to reduce lead times in CNC machining

CNC machining can be a costly and time-consuming process, especially when high precision is required. However, there are effective strategies to minimize lead times without compromising quality. Some of these design tips to optimize the CNC machining process and speed up the production of your parts are:

- Simplify design

- Reduce the number of configurations

- Minimize tolerances

- Choosing the right materials

- Minimizing material handling and worker effort

Ultimately, reducing manufacturing lead times in CNC machining is essential to improving efficiency and reducing costs. The best advice is to involve CNC machining experts from the design phase, ensuring that drawings are optimized for the machining process and can be produced as efficiently as possible.

Rapid prototyping at every stage of product development

The technology used for prototyping will depend largely on the stage of the product development cycle you are in. That is, in the early stages you may only need a prototype that represents a general idea for initial approval. As the project progresses, however, the prototype will likely need to consider factors such as form, function, performance, or manufacturability of the part.

Ultimately, the prototyping phase helps to validate the manufacturing process in a fast and cost-effective way, so the specific needs of each project must be taken into account.

How automation will drive the next generation of CNC machining

Automation is revolutionizing multiple industries, and CNC machining is no exception. As technology advances, the integration of automated systems into CNC machining promises to radically transform the way precision parts are manufactured.

As companies adopt these innovations, expect a major transformation in the way parts and prototypes are manufactured, leading the industry to new forms of performance and increased competitiveness.

In short, we can say that the key to making the most of these advances will be a continuous and strategic adaptation of the new emerging technologies. In this way, it will be possible to take full advantage of their benefits and innovations for the optimization of production processes.

At ProtoGo! we offer the best CNC machining service for your parts and prototypes. You can request your quote through our website quickly and easily.

What are you wating for? Request your quote now!